OEM Service

Metal Part Design and Manufacturing

Designs Midwest designs and manufactures metal parts for all types of industries. We have many years experience in designing and manufacturing parts for multiple manufacturing processes. Designs Midwest is able to determine the most effective and economic way a metal part should be designed and manufactured based on its yearly volume, application and finish requirements.

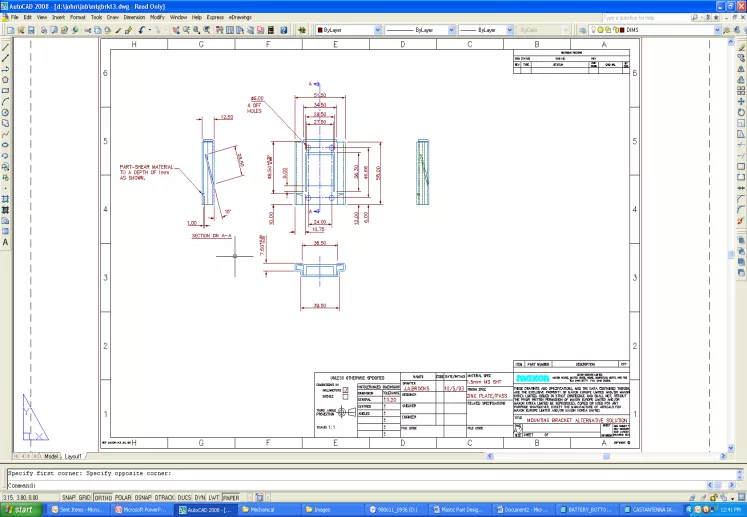

Part design is addressed in two ways either using 3D tools or if it is machined part or a simple sheet metal part by 2D fully detailed drawings see above examples of a Die Cast part in 3D and a simple sheet metal bracket fully detailed and dimensioned.

Designs Midwest offers multiple manufacturing processes for a wide range of metal parts:

● Pressure Die Casting for Aluminum, Magnesium and Zinc alloys

● Investment Casting

● Precision Sand Casting

● Sheet metal Stampings and Deep Drawing

● CNC Machining and Forming

● Extrusions

Designs Midwest has over the years designed and manufactured a wide range of metal components and products for multiple manufacturing methods and techniques.

Plastic Part Design and Manufacturing

Designs Midwest offers a wide range of plastic part design and manufacturing. We develop 3D files and 2D control document drawings for all plastic parts prior to starting the tooling process. 3D modeling enables the designer to control the data being used to develop the various tool designs and ensures an accurate transfer of information from the designer to the toolmaker.

A typical 3D Pro-E file of an injection molded part which includes draft angles and full dimensional data.

Designs Midwest offers multiple manufacturing Processes for a wide range of plastic parts:

● Injection molding from 50 ton to 450 ton machines.

● Blow molding

● Vacuum forming

● Rotational molding

● Plastic extrusion.

A wide range of Plastic parts Designed and Manufactured by Designs Midwest including Injection moldings, Extrusions and Blow molded parts.

Custom Membrane Switch Design and Manufacturing

Over many years, Designs Midwest has designed and manufactured a wide range of membrane switch products including overlays and industrial touch screens for a broad range of industries which are used in a large variety of applications. Designs Midwest continues to deliver membrane switches designed to work with signal currents – specifically, interfaced with a microprocessor or microprocessor-based module or system. Designs Midwest’s membrane switch products can be found in virtually any industry and application requiring a membrane switch utilizing a microprocessor control module or system.

We specialize in manufacturing membrane switches:

Overlay + circuit + LED + metal dome or poly dome array + connector + double side tape.

EL backlight + Rubber keys

Aluminum plate + Rubber keys

Metal domes

Flat without Tactile Feedback

Embossing with Tactile Feedback

Embossing with Metal Dome

Our experienced design and product management teams are ready to work with you to design custom membrane switches that will meet the unique requirements of your program. We offer a complete line of product features to provide you with the look, feel and performance that meets your needs. Designs Midwest offers textured keypads with clear windows for devices with LCD’s.

Metal Keypad Design and Manufacturing

We manufacture our metal keypad assemblies to satisfy customer specific applications such as custom language and function key output, custom dimensions and mounting styles and custom programming. Together with stringent quality control systems and OEM/ODM experience, we can assure the highest quality that enhances full functionality and capability.

Our metal keypads can be made of Stainless Steel or Cast Zinc, with custom dimensions, layouts and installation schemes. We can design and manufacture dustproof, waterproof, shake-proof, drill-proof and bullet proof assemblies. They can be made to IP 65 specifications. Other options are USB and PS/2 interfaces.

Design and Manufacturing

Designs Midwest offers design and manufacture of Capacitive Touch Sensing Technology switches. Capacitive touch sensors are used in many devices such as laptop trackpads, digital audio players, computer displays, mobile phones, mobile devices and others.

Today design engineers are selecting capacitive sensors for their versatility, reliability and robustness and cost reduction over mechanical switches. This technology is perfect for waterproof devices.

Rubber Keypad Design and Manufacturing

Designs Midwest has years of experience in the design and manufacture of silicone rubber keypads for a wide range of applications and industries. Today Silicone Rubber keypads are used extensively in consumer, automotive and industrial electronic products providing a low cost and reliable switching solution. This technology utilizes the superior compression molding properties of silicone rubber to create reliable and long lasting switches. Depression of a key uniformly deforms the webbing to produce the desired tactile response. When pressure is released, the webbing returns to its neutral position with positive feedback.

To create an electronic switch, a carbon or gold pill is bonded to the bottom of the key which makes contact with a pad on the printed circuit board upon depression of the key.

Designs Midwest provides excellent choices for both simple and the most stringent of design specifications. Unique processes allow light pipes and windows to be incorporated as an integral part of the keypad during manufacture, making them a single sealed component, less likely to fail or separate in use.

Designs Midwest has capabilities that include all molding processes, laser etching, screen printing, pad printing, in house graphics, and custom finishes offering an economical quality solution for your design requirements. Designs Midwest also offers plastic key tops according to customer needs.